Mining is all about quantities – how much to extract, how much to process, how much is being stored? Having reliable information to make informed decisions is essential for any site manager.

CHALLENGES

- Difficulty managing production to meet demand without accurate info on the level of stockpiles

- Either too much material being processed (and then needing storage) or not enough available to fill orders.

SOLUTIONS

- Manage production and control stock levels with regular measurements of stockpile volumes.

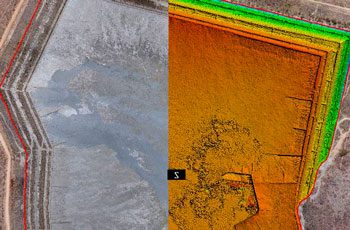

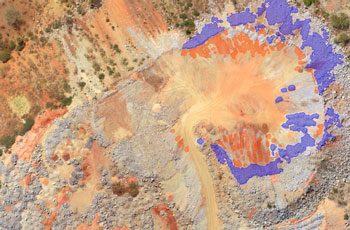

- Centimetre-accurate 3D models and georeferenced orthophotos for measurement and analysis

- Safe, quick and cost-effective data capture using drones and ground control with minimal disruption to operations

- Generate high-res orthophoto, digital surface models and volumetric reports

BENEFITS

- Quicker, safer and a fraction of the cost of using traditional methods of measurement

- Capture data in hours, not days without sending someone to walk up and down dangerous piles resulting in improved productivity and safety

- The precise digital surface area captured by the drone produces significantly more data points in comparison to a ground-based survey, resulting in more accurate calculations

- In conjunction with ground control, we can achieve surveys with 20-50mm accuracy,

- The ability to visualise the data and use accurate information results in better forecasting, decision-making, planning and inventory reporting.

Related Use Cases:

Landfill Surveys

Keeping track of landfill capacity is essential to making informed decisions on maximising capacity of the site.

Mine Management

Leveraging drones can dramatically reduce expensive and time-consuming activities required to manage mine sites.

Traffic Planning

Traffic management on mine sites is essential in reducing risk to workers and visitors.

Bathymetric Surveys

Using sonar sensors, we conduct bathymetric surveys to map underwater features and measure depths.